Views: 1 创始人: Site Editor Publish Time: 2025-04-13 Origin: Site

From the perspective of "reducing the manufacturing process,

saving costs, and reducing pollution", more and more electronic welding adopts

the post-weld "no-clean" process. However,

if there

are "solder

beads"

on the surface of the plate after welding, it cannot meet the

requirements of "no-cleaning", so "no-clean" is being

implementedIn the process, the prevention and control of "solder beads"

is particularly

important. "Solder beads" not only affect the appearance of

board-level products, but more seriously, due to the dense components on the

printed board, it may cause short circuits and other conditions during use,

which in turn affects the reliability of the product.

Based on the situation of the entire electronic soldering, the process

processes that may appear to be "solder beads" include: "SMT surface mount" soldering process

and

"wave

soldering".The manufacturing process and the "manual welding"

process, let's

discuss the causes of "solder beads" and the methods of

prevention and control from these three aspects one by one. Because

"wave

soldering" and "manual soldering" have been

implemented for many years, many aspects are relatively mature, so this article

devotes more space to the introduction of "SMT surface mounting"Causes and prevention and

control measures of "solder beads" in

the welding process.

<!--[if !supportLists]-->1.<!--[endif]-->About the

form and standard of "solder beads" Some industry standards have

explained the problem of "solder beads". The MIL-STD-2000 standard states that

"no

solder beads are allowed", while the IPC-A-610C standard states "less

than 5 per square inch".。 In the IPC-A-610C standard, solder

balls with a diameter of 0.13 mm are considered acceptable if the minimum

insulation clearance is specified, and solder balls with a diameter greater

than or equal to 0.13 mm are non-conforming, and the manufacturer must take

corrective measures to avoid this phenomenon. The latest version of the

IPCA-610D standard for lead-free soldering does not provide for a more explicit

description of the solder bead phenomenon, and the provision for less than 5

solder beads per square inch has been removed. Standards for automotive and

military products do not allow for any "solder beads",

and the circuit

boards used must be cleaned after soldering or removed by hand.

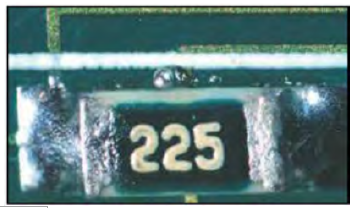

The photos of the common solder bead forms and their sizes are shown in

the figure below:

<!--[if !supportLists]-->1.<!--[endif]-->Causes and prevention and control methods of

"solder

beads"

in the "SMT

surface mount" process In the "SMT surface mount" soldering process,

reflow soldering".Factors such as temperature, time,

solder paste quality, printing thickness, stencil (template) production, and

mounting pressure may lead to the generation of "solder balls". Therefore,

finding out the possible causes of "solder beads" and preventing and

controlling them is the key to achieving no "solder beads" on the board

surface.

(1) The condition of "solder beads" that may be caused

by the quality of the solder paste itself

<!--[if !supportLists]-->1.<!--[endif]-->The metal content

in the solder paste. The mass ratio of the metal content in the solder paste is

about 89 - 91%, and the volume ratio is about 50%. Generally, the higher the

metal content, the tighter the arrangement of the metal powder in the solder paste,

the more opportunities for the combination of tin powder particles, and it is

not easy to be blown away during gasification, and it is not easy to form

"tin

beads"; If the metal

content decreases, the chance of "solder beads" increases.

<!--[if !supportLists]-->2.<!--[endif]-->The amount of oxide

in the solder paste. The oxide content in the solder paste also affects the

welding effect, the higher the oxide content, the greater the surface tension

when the metal powder is melted and fused with the pad, and in the

"reflow

soldering section", the oxide content on the surface of the metal powder

will also increase, which is not conducive to the complete

"wetting"

of the molten solder. This results in the production of fine solder beads.

<!--[if !supportLists]-->3.<!--[endif]-->The particle size

of the metal powder in the solder paste. The metal powder in the solder paste

is a very fine near-circular sphere, and the commonly used solder powder ball

diameter is about 25 - 45 μm, and the oxide content of the finer powder is low,

which can alleviate the "solder bead" phenomenon.

<!--[if !supportLists]-->4.<!--[endif]-->Solder paste

anti-thermal collapse effect. In the reflow soldering preheating section, if

the solder paste is not good in thermal collapse resistance, the printed solder

paste begins to collapse before the soldering temperature (before the solder

begins to melt), and part of the solder paste flows outside the pad, and when

it enters the soldering area, the solder begins to melt, due to the action of

internal stress, the solder paste shrinks into a solder joint and begins to

infiltrate and climb to the solder end, sometimes because of the lack of flux

or other reasons that lead to insufficient solder paste stress, a small part of

the solder paste outside the pad does not shrink back, and is formed after

complete melting".Tin beads".

It can be seen that the quality and selection of solder paste will affect

the production of solder balls, and the content of metals and their oxides in

solder paste, the particle size of metal powder, and the thermal collapse

resistance effect of solder paste all affect the formation of "solder balls" to varying

degrees.

(2) Analysis of the reasons for the formation of "tin beads"

due to improper use

<!--[if !supportLists]-->1.<!--[endif]-->"Solder beads" are produced when

they pass through the reflow oven. The reflow soldering process can be roughly

divided into four stages: "preheating, insulation,

soldering, and cooling". The "preheating section"

is designed to

slowly heat up the PCB and surface mount components to between 120 - 150°C, which removes

volatile solvents from the solder paste and reduces thermal shock to the

components. In this process, vaporization occurs inside the solder paste, and

if the adhesion between the metal powders in the solder paste is less than the

force generated by the vaporization of the flux, a small amount of

"solder

powder" will flow down or fly out from the pads, and in the

"welding"

stage, this partThe

"solder

powder" also melts, forming "solder beads".

From this, it can be concluded that "the higher the preheating temperature and

the faster the preheating speed, the vaporization of the flux will be

exacerbated, which will cause collapse or spatter and form solder beads". Therefore, we can

control the formation of "solder beads" with a moderate

preheating temperature and preheating speed.

<!--[if !supportLists]-->2.<!--[endif]-->The printing

thickness and amount of solder paste on the printed board. The printing

thickness of the solder paste is a major parameter in production, the printing

thickness is usually between 0.15 - 0.20mm, too thick or too much can easily

lead to "collapse", thus forming "solder beads".。 In order to avoid

excessive printing of solder paste, we control the size of the printed hole to

be about 10% less than the contact area of the corresponding pad, and the

results show that the phenomenon of "solder balls" can be reduced to

a certain extent.

<!--[if !supportLists]-->3.<!--[endif]-->If the placement

pressure is too large during the placement process, when the component is

pressed on the solder paste, a part of the solder paste may be squeezed under

the component, or a small amount of solder powder will fly out, and this part

of the solder powder will melt in the soldering section, thus forming

"solder

beads"; Therefore, the

appropriate placement pressure should be selected when mounting.

<!--[if !supportLists]-->4.<!--[endif]-->Solder paste

usually needs to be refrigerated, before using must be restored to room

temperature before opening the package, if the temperature of the solder paste

is too low to open the package, the surface of the paste will produce moisture,

these moisture will make the solder powder fly out when preheating, in the

soldering section will make the hot melt solder splash, thus forming

"solder

beads".

In the general area of China, the air humidity is high in summer, and when

the solder paste is taken out from refrigeration, it is generally necessary to

warm up at room temperature for 4-5 hours before opening the cap.

<!--[if !supportLists]-->1.<!--[endif]-->The production or

working environment will also affect the formation of "tin beads",

when the printed

board is stored in the humid warehouse for too long, fine water droplets are

found in the packaging bag containing the printed board, and these moisture are

the same as the moisture absorbed by the solder paste, which will affect the

welding effect, thus forming "tin beads". Therefore, if

conditions permit, the printed board or components are dried to a certain

extent before mounting, and then printed and soldered, which can effectively

inhibit the formation of "solder beads".

<!--[if !supportLists]-->2.<!--[endif]-->The shorter the

time the solder paste is in contact with air, the better, which is a principle

of using solder paste. After taking out a part of the solder paste, the lid

should be covered immediately, especially the cover inside must be pressed down

to squeeze out the air between the cover and the solder paste, otherwise it

will affect the life of the solder paste, and at the same time will make the

solder paste dry faster or absorb moisture in the next use, thus forming

"solder

beads".

It can be seen that there are many reasons for the emergence of

"tin

beads",

and it is far from

enough to prevent and control them from a certain aspect. We need to study how

to prevent various unfavorable factors and potential hidden dangers in the

production process, so that the welding can achieve the best results and avoid

the generation of "solder balls".

<!--[if !supportLists]-->1.<!--[endif]-->Prevention and control of

"solder

beads"

in the "SMT

surface mount" process

<!--[if !supportLists]-->2.<!--[endif]-->Selection of solder

paste When selecting solder paste, it should be tried under the existing

process conditions, so as to not only verify the applicability of the

supplier's solder paste to its own products and processes, but also to

preliminarily understand the specific performance of the solder paste in actual

use. When evaluating solder paste, it is important to pay attention to various

common parameters, such as the ratio of solder oil to solder powder,

the granularity of solder balls, etc.

The right selection of solder paste is not necessarily the best in all

parameters, but more often than not, the right one is the best for the SMT

process and product characteristics. Therefore, select the solder paste

suitable for your own process and product, and determine all the parameters, as

the basis for quality control acceptance and quality inspection in the future

supplier delivery process, on the one hand, check the written information

provided by the supplier, and on the other hand, take a small number of

different batches of products for trial.

High-quality suppliers will put forward corresponding process suggestions

in the process of cooperation, and upgrade and improve defects of solder paste

products according to the specific requirements of customers; Therefore,

relatively stable suppliers with high integrity can provide customers with

great help in preventing and controlling "solder beads" in terms of solder

paste quality.

<!--[if !supportLists]-->1.<!--[endif]-->"SMT surface mount" process control and improvement In all process control processes, there are strict document regulations from the preservation, removal and use, reheating to stirring of solder paste, mainly in the following key aspects:

(1) Storage in strict accordance with the storage conditions and temperature provided by the supplier, under normal circumstances, solder paste should be stored under refrigerated conditions of 0 - 10 °C;

(2) After the solder paste is taken out and before use, it should be warmed up at room temperature, and it should not be opened before the solder paste is completely warmed up;

(3) In the mixing process, the mixing should be carried out in accordance with the mixing method and mixing time provided by the supplier;

(4) In the printing process, attention should be paid to the strength of printing and the cleanliness of the surface of the steel mesh, and the excess solder paste residue on the surface of the steel mesh should be wiped in time to prevent the contamination of the PCB surface in this process, resulting in the generation of solder balls in the soldering process.

(5) In the process of reflow soldering, the operation should be carried out in strict accordance with the determined reflow soldering curve, and should not be adjusted at will; At the same time, the difference between the reflow soldering curve and the standard curve should be checked and corrected frequently;

(6) In the

"SMT surface mounting" process, the

"opening method" of the stencil (template) and

".The

opening ratio "is likely to cause some defects in the

solder paste in terms of "printing characteristics"

and

"welding

characteristics", which can be caused".Tin beads". In the relevant

experiments, we have improved the steel mesh, changing the original

1:1 steel mesh opening of the sheet element that is easy to produce "solder

beads" to a

wedge shape of 1:0.75, and the improved test effect is better"The probability of

occurrence has decreased significantly until it is almost eliminated.

By modifying the opening method of the stencil and the batch printing test, it can be clearly seen that the improved stencil opening method can effectively prevent and control the generation of "solder balls". The printing effect and welding effect of the modified "anti-tin bead" stencil are shown in Figure 2:

According to the multiple comparison experiments and combined with "Figure 2",

it can be seen that

through the comparison of the effects of the three modifications before and

after, there are no obvious solder beads in the steel mesh after the second

modification, and the amount of solder paste is not too small. This shows that

the change of the stencil opening has a certain effect on the prevention and

control of "solder

beads"

in the

"SMT

surface mount" process. At the same time, we will send the

changed soldering products to the "Saibao laboratory"

for testing (report

number "FX03 -

2081691"), and the 0603 components on the circuit board will be

tested for push-shear forceThe shear

forces of the five component points of "R124, R125, R126, C16, C57"

are respectively“58.14N、56.53N、51.87N、50.90N、52.35N”The welding strength can meet our requirements.

Although

the

prevention and control of "solder beads" in the "SMT surface mount"

process is

relatively complex, after long-term efforts and experience accumulation, it is

believed that no "solder beads" can be achieved, or effectively

reduced. solder beads".

<!--[if !supportLists]-->1.<!--[endif]-->Causes and

prevention and control methods of "solder beads" in the process of "wave soldering" In the

process of

"wave soldering", ". There are two situations for the generation of

"tin beads": one is that when the board is just in contact with the

tin liquid, due to the excessive moisture of the flux or the plate itself or

the high boiling point solvent is not fully volatilized, it suddenly

volatilizes when it encounters the tin liquid at a higher temperature, and the

large temperature difference causes the liquid solder to splash out and form fine

tin beads; Another situation is that when the circuit board leaves the liquid

solder, when the circuit board is separated from the tin wave, the circuit

board will pull out the tin pillar along the direction of the pin extension,

and under the wetting effect of the flux and the fluidity of the tin itself,

the excess solder will fall back into the tin cylinder, and the splashed solder

will sometimes fall on the circuit board, thus forming "solder beads".

Therefore, in terms of "wave soldering" prevention and control of "solder beads", we should start from two major aspects, on the one hand, the selection of raw materials such as flux, and on the other hand, the process control of wave soldering.

(1) Analysis of the causes of flux and prevention and control methods

<!--[if !supportLists]-->1.<!--[endif]-->The moisture

content in the flux is large or exceeded, and it fails to fully volatilize when

it is preheated;

<!--[if !supportLists]-->2.<!--[endif]-->There are high

boiling point substances or non-volatile substances in the flux, which cannot

be fully volatilized when preheated;

Both of these causes are caused by the "quality"

of the flux itself, which can be solved by "increasing the preheating

temperature or slowing down the walking speed" in the actual soldering

process.

In addition, before selecting flux, the actual process should be confirmed for

the samples provided by the supplier, and the standard process at the time of

trial should be recorded, and in the absence of "solder beads", other instructions

provided by the supplier should be reviewed, and the supplier's initial

description should be checked in the subsequent receipt and acceptance process.

(2) Analysis of the causes of the process and prevention and control

methods

<!--[if !supportLists]-->1.<!--[endif]-->The preheating

temperature is low, and the solvent part of the flux is not completely

volatilized;

<!--[if !supportLists]-->2.<!--[endif]-->The speed of the

board is too fast to achieve the preheating effect;

<!--[if !supportLists]-->3.<!--[endif]-->The inclination

angle of the chain (or PCB board surface) is too small, and there are bubbles

in the middle when the tin liquid is in contact with the soldering surface, and

tin beads are generated after the bubbles burst;

<!--[if !supportLists]-->4.<!--[endif]-->The amount of flux

applied was too large and the excess flux did not flow away completely or the

air knife did not blow the excess flux off.

The occurrence of these four bad causes are related to the determination

of the standardized process, in the actual production process, should be in

strict accordance with the work instruction documents that have been formulated

for the correction of the parameters, the parameters that have been set can not

be changed at will, the relevant parameters and the technical level involved

mainly have the following points: (1) About preheating:

generally set at 90 °C - 110

°C, as mentioned here"Temperature"

refers to the

actual heating temperature of the soldering surface of the PCB board after

preheating, rather than the "apparent" temperature; If the

preheating temperature does not meet the requirements, it is easy to produce

solder beads after soldering. (2) About the speed

of the board: under normal circumstances, it is recommended that the customer

set the speed of the board at 1.1 - 1.4 m/min, but this is not an absolute value; If you want to change the speed of

the walking board, it should usually be matched by changing the preheating

temperature; For example, in order to speed up the board walking speed, in

order to ensure that the preheating temperature of the PCB soldering surface

can reach the predetermined value, the preheating temperature should be appropriately

increased; If the preheating temperature remains the same, the flux may not

evaporate completely if the pass speed is too fast, resulting in the formation

of

"solder

beads"

during soldering. (3) Regarding the inclination angle of the

chain (or PCB board surface): this inclination angle refers to the angle

between the chain (or PCB board surface) and the tin liquid plane, when the PCB

board walks through the tin liquid plane, it should be ensured that the PCB

part surface and the tin liquid plane have only one tangent point, and there

can be no large contact surface; When there is no inclination angle or the

inclination angle is too small, it is easy to cause bubbles in the middle when

the tin liquid is in contact with the welding surface, and the bubbles will

burst to produce "tin beads". (4) In the use of wave furnace, the main function of the

"air

knife"

is to blow off the

excess flux on the PCB board surface, and make the flux evenly coated on the

PCB part surface; Under normal circumstances, the inclination angle of the air

knife should be about 10 degrees; If the angle adjustment of the

"air

knife"

is unreasonable, it

will cause too much flux on the surface of the PCB, or the coating will be

uneven, which will not only be easy to drip on the heating element when it

passes over the preheating area, affecting the life of the heating element, but

also easy to cause the phenomenon of "fried tin" when immersed in the

tin liquid. And as a result, "tin beads" are produced.

In the actual production, combined with the actual situation of its own

wave soldering, the relevant materials are selected, and at the same time,

strict "wave soldering operation procedures" are formulated, and

production is carried out in strict accordance with the relevant regulations.

Experiments have proved that under the condition of strict implementation of

process technology, it is completely possible to overcome

the "solder

beads" caused

by "wave

soldering process problems".

<!--[if !supportLists]-->1.<!--[endif]-->Causes and prevention and control of "solder

beads" in

the process

of "manual soldering" In the process of "manual soldering", "solder beads"The

probability of occurrence

is not high, the common is rosin splashing, occasionally there will be

"solder

beads"

splashing or solder

residue on the surface of the pad; Compared with rosin splashing,

the presence of "tin beads" or solder dross is more potentially

harmful to product safety.

The main reason for the occurrence of solder dross and

"solder

beads"

may be: the flux

has completely evaporated before the heat source is removed, resulting in

extremely poor solder fluidity, and the sticking soldering iron tip forms a

tip, column or short solder with the soldering iron extraction, or the solder

liquid is accidentally splashed away from the soldering iron tip and adheres to

the board surface or component after cooling. Another possibility is that the

soldering wire is not preheated by placing the soldering tip on the soldered

part first, but the solder wire is ironed first, and then placed in the

soldered position, which causes solder spatter due to a large temperature

difference, resulting in the formation of "solder beads".

Regardless of the above reasons, it is more important to teach the

operator to grasp the correct soldering time and position, add the appropriate

amount of solder, and pay attention to cleaning the soldering iron tip in a

timely and correct manner. In actual production, special welding technology

training is often carried out for "manual welding" employees, and the

"manual welding process requirements" are strictly compiled to

standardize and control the process requirements for "manual welding". Through long-term

observation, the generation of "solder balls" can be effectively

avoided in the process of "manual welding operation".

Conclusion: For the problem of "solder beads", we spent more than

half a year, did a lot of experiments with relevant customers, and conducted a

detailed analysis of different welding processes. Practice has proved that

through material selection, process control and other measures, it is entirely

possible to eliminate or reduce the probability of "solder balls" in the current

electronic welding process.

Looking forward to the future, a series of in-depth re-studies will be

carried out on the formulation and production process of solder paste,

including "the selection, compatibility and ratio of solvents, rosin

resin, activators, thixotropic agents, surfactants and other types of additives

in solder paste, as well as the temperature, time and other aspects involved in

the production process of solder paste". It is hoped that the

generation of "solder balls" can be solved or prevented from the

perspective of product technology, so as to ensure that the occurrence of "solder

balls" is

eliminated or reduced in the welding process, so as to cooperate with more customers

to achieve "no cleaning" after welding"Craftsmanship.

苏公网安备32058302004438

苏公网安备32058302004438